Screen printing, a.k.a. “silk screening,” is often the most economical option to help your organization make a big impression. Most customers are looking for some of the most universal apparel items around — screen printed t-shirts and screen printed hoodies, which are inexpensive to start. Then add the fact that the screen printing process is essentially setting up a little factory for your own shirts. The fixed costs, which are set-up charges and any charge for conversion of artwork are spread over the entire run. Insufficient quantities, pricing for screen printed t-shirts, even with multiple colors, can approach a mere $6 per shirt!

Screen printing, a.k.a. “silk screening,” is often the most economical option to help your organization make a big impression. Most customers are looking for some of the most universal apparel items around — screen printed t-shirts and screen printed hoodies, which are inexpensive to start. Then add the fact that the screen printing process is essentially setting up a little factory for your own shirts. The fixed costs, which are set-up charges and any charge for conversion of artwork are spread over the entire run. Insufficient quantities, pricing for screen printed t-shirts, even with multiple colors, can approach a mere $6 per shirt!

Pricing for screen printing on a garment is the same regardless of the size of the image. So while the full back side of a screen printed shirt might cost anywhere from $1-$5 to print, depending on the number of colors and the quantity of shirts, embroidering the same design might cost $60-200 due to the time required to embroider each stitch into the garment. So screen printing is a pretty great deal considering the image size you get.

Build Your Own Spot Screen Printing Quote

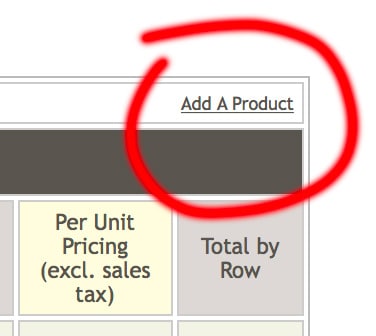

Start the quote by clicking on the “Add A Product” link in the upper right.

Start the quote by clicking on the “Add A Product” link in the upper right.We offer:

Spot Color Screen Printing (up to 6 colors)

Half-Tone Screen Printing

Oversized Printing

4 Color Process Screen Printing

Simulated Process Screen Printing

Water-Based Screen Printing

Water-based screen printing is fast becoming the rage as the newest, best thing in screen printing. In fact, it is the original method of screen printing fabrics, long before plastisol (oil-based) inks were introduced and became so common. Water-based screen printing has some nice advantages over plastisol:

- You get a soft feel because the ink soaks into the fabric and dyes the fabric itself, instead of resting on top of the fabric.

- You can achieve a matte or even “faded” look right off of the press.

- It is a more environmentally friendly method of screen printing.

It does come with some caveats for the consumer. It does not work well with cheap grade cotton tees. The consumer has to want higher quality ring-spun cotton or blended fabric t-shirts. The printing process itself requires some environmental controls to properly set up the screens. All that means that the consumer needs to be prepared to spend more per shirt.